Diesel Engines Guide - How Do Diesel Engines Work?

Diesel engines power everything from cars, trucks, ships and more

Diesel is the backbone of many UK industries, powering everything from heavy-duty trucks to construction equipment and even ships on our seas. Providing power to vehicles, diesel is a necessity in modern life, but what are the components of a diesel engine? Does it provide the same efficiency as a standard gas engine? Learn this and more in our guide.

If you still have further questions about the use of diesel within modern engines and machines, or if you’d like to discuss your own diesel requirements with our fuel experts, you can do so by calling us on 0330 123 1144.

What is a diesel engine?

Diesel engines are a type of internal combustion engine that uses compression ignition to convert the energy from diesel fuel into energy for powering machinery and vehicles.

How does a diesel engine work?

There are different types of diesel engines, which we’ll go into further down this guide. Though there are many versions of diesel engines, the systems are broadly similar, mainly due to most of the engines being four-stroke diesel engines.

Prior to your engine working you’ll need to fuel your vehicle or machinery with diesel fuel. Your fuel will pass through a fuel filter which will then remove any particles that may get lodged in your engine, including diesel bug or dirt.

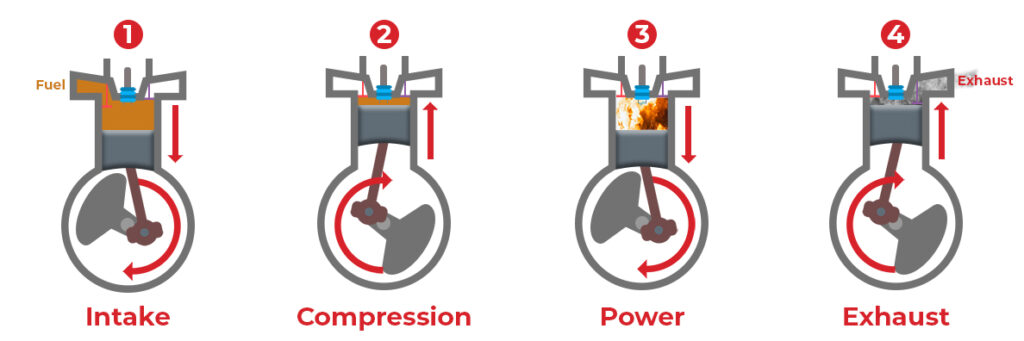

How does the process of a diesel engine actually work?

Intake stroke – The first stroke is the intake stroke which determines the correct amount of fuel that is brought into the fuel injection system. It is then mixed with air in the piston, where it becomes compressed.

Compression stroke – The intake valve now closes and the compression process starts compressing air with fuel.

Combustion stroke – The intense pressure of the fuel and air releases fumes of ignited diesel fuel.

Exhaust stroke – Additional combustion gases are then forced out of the exhaust fuel, through the exhaust manifold and into your exhaust.

How important are diesel engines?

The importance of diesel engines cannot be understated, they power vehicles all over the world due to diesel’s specific characteristics. Firstly, the efficiency of diesel fuel means there is more power per unit of diesel than other fuels. Diesel engines also provide a high torque which enables the rotational force to move heavy loads with relative ease. This makes it ideal for trucks, construction equipment and large machinery.

The durability of a diesel engine also makes it a must for industries up and down the country. Due to their longevity and reliability, they are the perfect choice for many heavy goods vehicles and industries where powerful machinery is required. They will continuously operate even in harsh conditions. The power density of a diesel engine is also efficient and offers a high power-to-weight ratio making them compact; particularly useful when space is lacking.

Who Invented the diesel engine?

The diesel engine was designed in Paris in the 19th century, by a German engineer named Rudolph Diesel. His idea was to create a highly efficient engine, through meticulous development and planning he successfully created a prototype in 1893.

His design ran on the compression of air to ignite the fuel, instead of a spark plug which is how other engines ran. Although Mr Diesel is credited with the invention of the diesel engine, significant improvements and continuous refinement of the engine have occurred since its invention. Thanks to advances in materials and technologies a more modern, reliable and scaleable version now exists.

Diesel engines vs petrol engines

| Engine Feature | Diesel Engine | Petrol Engine |

| Fuel Efficiency | Higher fuel efficiency, especially when driving long-distance | Lower when compared to diesel but there have been significant improvements |

| Power Output | Higher torque makes diesel the better choice for heavier loads and acceleration | High horsepower provides higher speeds |

| Emissions | High in particulate matter and NOx but improvements in technology have massively reduced diesel emissions | Lower emissions when compared to older diesel models though the petrol engine does have a higher CO2 output |

| Maintenance Costs | Higher and more complex components resulting in higher-quality fluids | Low overall maintenance costs |

| Initial Costs | Diesel engines provide a more complex engine making upfront costs more expensive | Significantly lower costs than diesel engines |

Types of diesel engines

Diesel engines predominately fall into two categories, which is based on their combustion cycle:

Four-stroke diesel engines – The most common type of diesel engine, which completes a full cycle in four strokes of the piston through intake, compression, power and exhaust. Diesel engines are used in various vehicles and applications including cars, lorries, generators and marine vessels.

Two-stroke diesel engines – A much simpler design, these engines are able to complete a cycle within just two strokes. They are engines which are larger and usually found in heavy-duty applications including power plants and large marine vessels,

Advantages of diesel engines over petrol engines

Due to their efficiency and performance, diesel engines have earned a reputation for being reliable engines for a variety of vehicles and applications.

Fuel Efficiency – Offering a better fuel economy when compared to gas engines, diesel engines are a cost-effective choice for heavy-duty applications and long-distance travel.

Higher Torque – A diesel engine can provide more torque, which is a measure of its pulling power and acceleration. This makes them an ideal choice for towing and off-road usage.

Durability – Renowned for their robustness and long lifespan, diesel engines can withstand demanding conditions that require much less maintenance than a gas engine.

Reduces Emissions – A modern diesel engine produces far lower levels of emissions than older iterations, specifically particulate matter and nitrogen oxides.

Disadvantages of a diesel engine over petrol engines

Although there are plenty of advantages to diesel engines, there are also some drawbacks:

Higher initial cost – Diesel engines tend to be a more expensive purchase initially, as they are more technical to build compared to gas engines.

Noise – Diesel engines tend to be noisier, due to the vibrations from the diesel engine, although recently this issue has been minimised.

Emissions – Although we have included emissions in the advantages of a diesel engine they do still produce higher levels of nitrogen oxide when compared to petrol engines.

Cold weather difficulty – A diesel can be challenging when starting in cold conditions as the fuel is thicker.

Does a diesel engine need regular maintenance?

When maintained diesel engines are renowned for being reliable, efficient and long-lasting engines. This means you’ll need to regularly service your engine, which does result in replacing worn components, fluids and oils. Keeping your engine well lubricated will keep your engine cool, and provide a high level of performance.

Diesel engine key component jargon buster

After-treatment system – This is a method or device that is designed to reduce harmful exhaust emissions from internal combustion engines. Essentially this will clean your exhaust gases to ensure your engine meets emission regulations.

Battery – Provides electricity that allows the engine to start and power the vehicle’s electronics and accessories.

Diesel exhaust fluid – This fluid helps reduce your diesel fuel emissions, it is also known as Adblue and contains 32.5% of Aqueous urea Solution.

Diesel exhaust fluid tank – Holding your diesel exhaust fluid

Diesel exhaust fluid filter – A filter which collects and stores exhaust soot to reduce harmful emissions released from your diesel engine.

Electronic control module – This computer provides a smooth operation of your diesel engine by monitoring and collecting data positioned throughout your engine and vehicle.

Fuel filter – This part of a diesel engine will remove the impurities of your diesel fuel before it reaches your fuel injector.

Fuel lines – A hose which carries the fuel from a tank to the injector.

Fuel pump – Pumps your fuel from the tank into the fuel injector.

Internal combustion engine – An engine which generates power by burning fuel, oil or in this case diesel.

Transmission – Used to transfer power from an engine to the wheels of a vehicle. The design changes differently depending on the vehicle it is pushing as heavy goods vehicles need high torque and tow demands.

Turbochargers – The job of a turbocharger is to compress air that flows into the engine’s cylinder. The pressure created by the turbocharger compacts the air molecules to generate power.

If you’d like to learn more about our diesel fuel and other oils and lubricants. Give our diesel experts a call today on 0330 123 1144 regarding your current fuel usage, and see if our services can improve your vehicles or machinery performance.

Free Online Quote

The benefits of using Beesley Fuels

24 – 48 hour Standard Delivery

We deliver on our promise, with 92% of our orders successfully delivered within 24 hours.

24/7 Emergency Delivery

We can come to your rescue with our emergency deliveries, helping you avoid unplanned downtime.

Sustainable Fuelling Solutions

We don't just supply fuel, we have the tools and expertise to help you fuel your business responsibly.

Personal Account Managers

With us, you’ll have one point of contact throughout, who will know your fuel needs inside out.