Crude Oil and Fractional Distillation Guide

The process of fractional distillation is a way in which a range of fuels, lubricants and oils are extracted from crude oil. These fuels, oils and lubricants are created to help power our diesel road vehicles, and machinery as well as keep homes and workspaces heated.

But how exactly do we turn these well-known products into several fuels and lubricants from just one oil?

Find out how fractional distillation works, and what we extract from crude oil in the process below, if you have any other questions don’t hesitate to call us on 0330 123 1144.

What is crude oil?

Essentially, crude oil is a black oil that is made up of complex organic hydrocarbon structures formed from living matter which existed millions of years ago. That matter has now been processed through geological forces which turns it into its current form of black crude oil.

The vast majority of the crude oil in the UK comes from oil fields located within the Middle East, with Saudi Arabia providing the biggest import of UK crude oil.

What is fractional distillation?

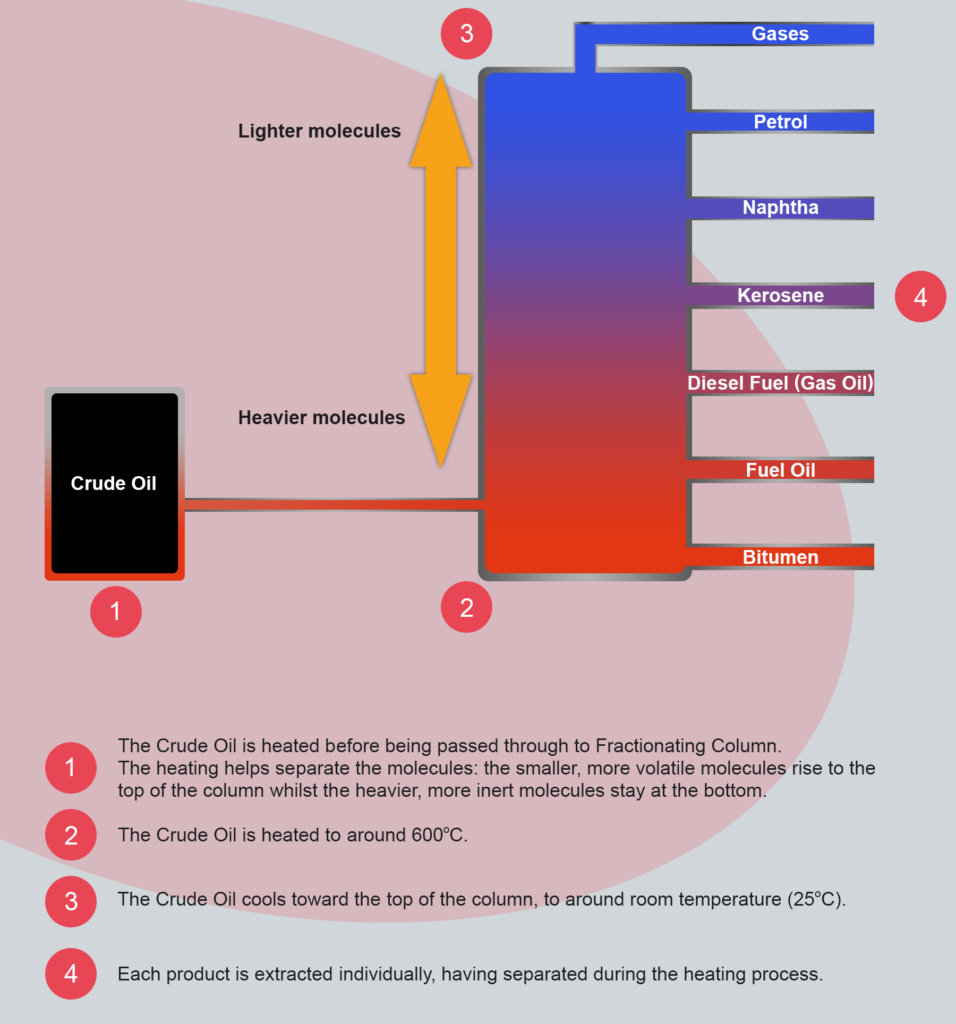

You may have heard of the process of fractional distillation but what does it mean and how does it work? The process begins with boiling the crude oil mixture which releases the different liquids as gases. The gases that are created will rise within the fractional column and condense at a cooler point within the column. The coolest parts of the column are within the higher sections of the column, whereas the hottest sections are at the bottom and are often heavier fuels used in marine diesel shipping.

How fractional distillation works

This is a process which is used to separate different liquids from a mixture of liquids, and in our case, used to separate different fractions of crude oil. It works by heating the crude oil to an extremely high temperature, which is done within the fractionating column – hence the name, fractional distillation. When heated, the crude oil transforms from oil into groups of hydrocarbons, rising through the column and separating at different temperature zones, extracting each component. Products will be obtained at almost all temperature zones, from 600 degrees at the very bottom of the tank, which is the hottest area of the tank, to the coolest sections at the top of the tank with temperatures as low as 25 degrees.

Within these separated temperature zones you’ll find:

Breakdown of the fractional column

Top distillates

Within the top of a fractionating column are the risen gases and liquids which have short carbon chains. These products are often used as fuels but they also have industrial and chemical uses too.

Petroleum Gases

The coolest section of the column is the top column where gases such as petroleum, propane and butane are formed, this section has a temperature of around 25 degrees. Out of all of the products formed from crude oil distillation, these are the lightest products but are flammable gases.

Petrol

The most universally common fuel from crude distillation is petrol which is used mainly as an engine fuel within vehicles. As much as 60% of crude oil is refined into petrol, which is why it is so important for renewable alternatives to be created.

Naphtha

Naphtha is known for its use within the chemistry and industrial sectors to help produce plastic as well as fluids such as lighter fluids. It has a boiling point of 60 to 100 degrees and contains between five and twelve carbon atoms per molecule.

Middle distillates

Fuels that fall into this category have a higher flashpoint of over 42 degrees and are classified as fuel oil. Fuel oils are middle distillates as they form in the mid-section of the fractional column.

Paraffin

Used as a domestic heating and burning application, paraffin and paraffin wax form within the fractional column between 100 and 175 degrees. Paraffin wax is often further processed to be used in the creation of candles, petroleum jelly along with many other well-used products.

Kerosene

Forming when temperatures for condensation are around 175 degrees to 250 degrees, kerosene is used as a home heating oil (BS 2869 grades C1 kerosene and C2 kerosene) and for jet fuel (A1 jet fuel).

Diesel

Diesel fuels condense over a range of boiling temperatures, between 250 degrees to 350 degrees. Petroleum diesel is the fuel that we use in our diesel-engined automobiles as well as for agricultural machinery and heating applications.

Lower distillates

Located at the bottom of the fractionating column, lower distillates have much higher densities and boiling points. They are therefore not used as fuels, and more often than not are used as grease for lubrication.

Lubricating oil

Lubricants which are mineral-based and often used within equipment and machinery are distilled from this part of the fractionating column, with the most common being motor oil. These lubricants are formed when temperatures within the column are 300 degrees to 350 degrees.

Bunker fuels and heavy fuel oil

These are a specialist fuel which is to be used specifically within vessels, typically larger ones, as small vessels tend to run on regular white diesel. Find out more in our bunker fuel guide.

Marine gas oil (MGO)

Marine gas oil is our most common form of vessel fuel and is used more so in larger vessels.

Heavy fuel oil (HFO)

The larger vessels within our oceans run on heavy fuel oil, however, since 2020 the International Maritime Organisation has changed the rules to phase out HFO by 2024, for a lighter, lower sulphur marine gas oil.

Marine fuel blends

These are made of three maritime oils, MDO, IFO and MFO and are produced by blending a variety of proportions of MGO and HFO.

Marine diesel oil (MDO)

Produced from a blend of distilled diesel fuel and a small amount of heavy fuel oil (HFO).

Intermediate fuel oil (IFO)

A heavier oil is made using a blend of HFO and MGO, however, this has slightly more heavy fuel oil than what marine diesel oil uses.

Marine fuel oil (MFO)

Again, MFO is slightly heavier as this contains more heavy fuel oil than the above blends, which results in a black-coloured oil.

Residuals

The residue that is formed at the bottom of a fractionating column includes bitumen and asphalt. When petroleum products are formed during a burning process, waste must be kept to a minimum, so at the bottom of the fractionating column the residue, bitumen and asphalt are put to use.

Bitumen

refined bitumen product is formed from the residue of petroleum and where the column reaches around 600 degrees. This is an essential product you will come across daily, as it is a key component of the construction sector that is used within tarring roads and sealing roofs.

Asphalt

Asphalt forms naturally and is known as crude bitumen.

Types of crude oil

Very light oil – This includes jet fuel, kerosene, petroleum ether, petroleum spirit, and many more oils that are classified as very light oil.

Light oil – This includes the likes of Grade 1 and Grade 2 fuel oils as well as a range of domestic fuel oils

Medium oil – These are the most common types of crude oil which have a low volatility and high viscosity when compared to light oils, leading to higher toxicity and a bigger impact on the environment.

Crude Oil vs Petrol

Petrol and crude oil are interchangeable when looking at the refinement and production of the two products. Petroleum is a blanket word for different fuels, and petrol and crude oil fall into this category. Even though they are similar, crude oil specifically refers to the raw products drilled from the ground.

For more information on crude oil, or any of the oils, lubricants and gases we have mentioned in this guide, you can speak directly to our fuel experts on 0330 123 1144.

Free Online Quote

The benefits of using Beesley Fuels

24 – 48 hour Standard Delivery

We deliver on our promise, with 92% of our orders successfully delivered within 24 hours.

24/7 Emergency Delivery

We can come to your rescue with our emergency deliveries, helping you avoid unplanned downtime.

Sustainable Fuelling Solutions

We don't just supply fuel, we have the tools and expertise to help you fuel your business responsibly.

Personal Account Managers

With us, you’ll have one point of contact throughout, who will know your fuel needs inside out.